Faultless and efficient operation?

Are you looking for a way to cut personnel costs for your food safety lab? We developed the Kitty plate inoculating robot, which lets one person fill more than 360 Petri dishes per hour. This high quality machine delivers considerable cost savings.

The Kitty automated plate inoculating robot - operation

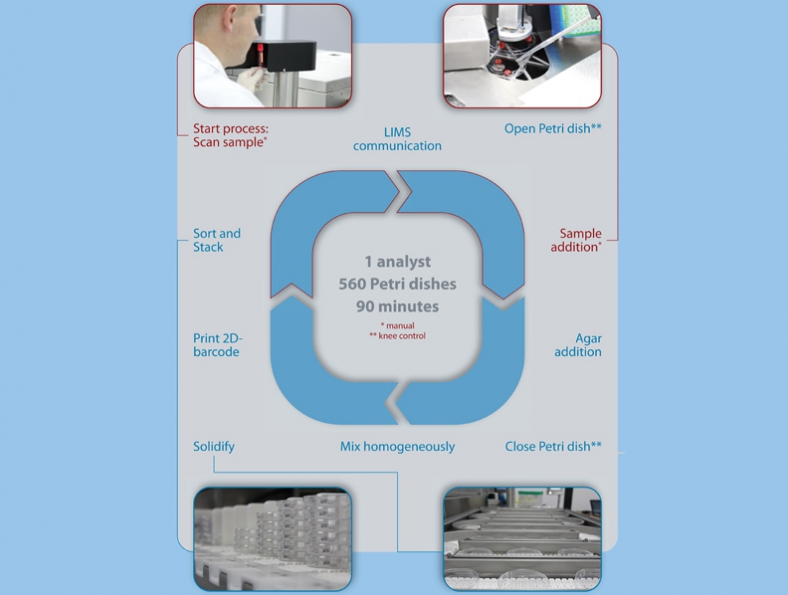

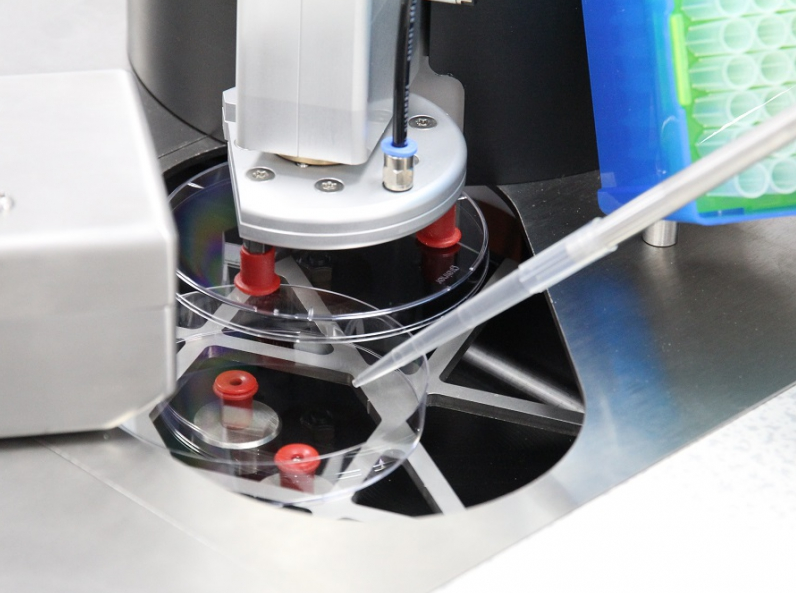

Various automatic operations take place simultaneously in the average processing time of 10 seconds per dish:

- Fetching, opening and filling the empty petri dish with agar.

- Adding the sample

- het sluiten, schudden, terugkoelen en coderen van de petrischaal;

- Closing, agitating, re-cooling and coding the petri dish

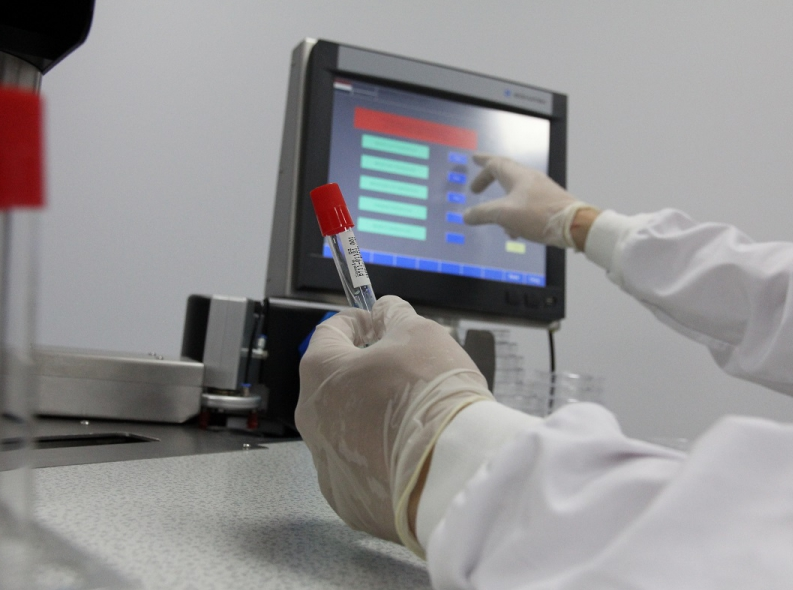

- Communicating with the Laboratory Information Management System (LIMS). See the demo or more extensive product information.

Advantages Plating machine Kitty

- Fast (10 sec / Petri dish)

- Accurate

- Human variations minimized

- User friendly

- Processing special samples is possible

- Low maintenance contract

- 2D barcoding

- Communication via LIMS

- Small footprint (1.5m x 4m)

The Kitty plating machine: product information

The plating machine performs microbiological analyses and is a remarkably compact workhorse for your food safety lab. The machine has high-quality electronics and is low-maintenance. With storage capacity for 560 empty petri dishes, eight medium pumps and ten sorting-and-stacking units, one operator can fill petri dishes continuously in a two-hour operation. This type of machine has been around for twenty years and has been successfully used by SGS Netherlands, SGS Portugal and ILS England.

Would you like more information?

Would you like faultless and efficient operation in your laboratory too? The Kitty plating machine makes this possible. Call us for an obligation-free appointment on + 31 (0)71 3310085 of fill in the contact form. .

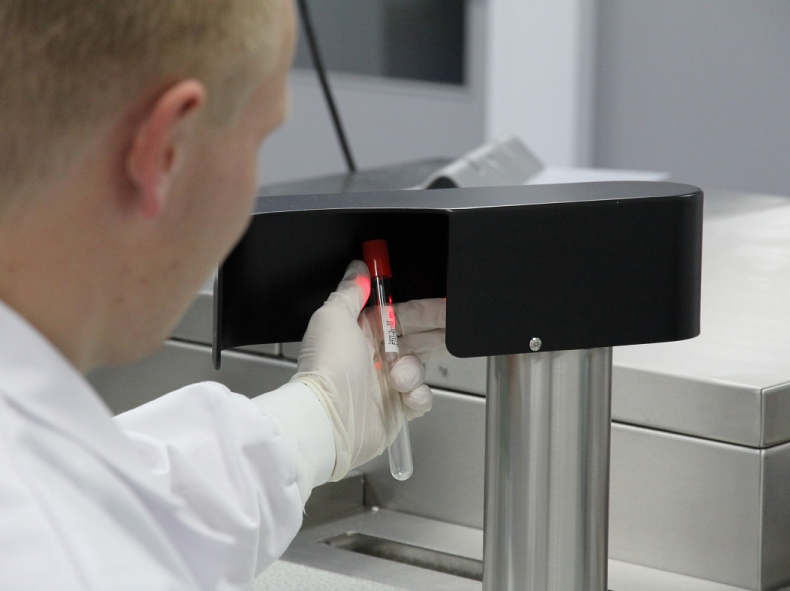

The Kitty plating machine: working method

The operator follows the instructions on the screen for processing the sample, scanning the barcode of the sample tube, pipetting and dosage. He then operates the knee pedal. While the correct medium is automatically flowing into the Petri-dish, the operator adds the sample in one single smooth action using the pipette pistol, then discharges the used tip, clicks on a new one and the process is then repeated. One person can run 350 Petri-dishes per hour with this system. Watch the demo-film.

The Kitty plating machine: technical specifications

Specifications:

- 1.5 x 4 metres

- Mechanical speed 7.5 seconds per tact (approximately 480 dishes in theory)

- Heated dosage arm

- Storage unit with treatment area

- Vibration conveyor belt

- Cooling belt

- Sorting and stacking unit

Capacity:

- 560 empty Petri-dishes

- 8 medium pumps

- 10 sorting/stacking units for, among others, Cfu, Entero’s, Staph. Aureus, Lactic acid, yeasts and moulds

- 1 operator

- Can be connected to LIMS

- Coding of Petri-dishes with unique barcode

- Sorting machine which sorts on a basis of medium and places special samples aside

Components:

- 1 touch-screen

- 8 hose-pumps

- 1 stepper motor

- 2 servo-motors

- 26 DC motors

- 4 temperature sensors

- 1 heater

- 1 ventilator

- 1 heating element

- 2 rotating cylinders

- 3 vacuum groups

- 13 air cylinders

- 20 valves

- 24 optical sensors

- 42 inductive sensors

- 31 air pressure-related sensors

- 1 barcode printer

- 1 barcode scanner

- 1 cooling transformer